EV Batteries Second Life Components of an EV Battery Battery Management Systems

EV battery disposal Environmental impacts Best Practise Specialist Re-Cycling

Commodity Brokerage Black Mass Alternative Battery Technology FAQs

EV Battery Disposal – Many of us have experienced the frustration of buying a new phone or laptop with excellent battery life, only to have it decrease over time until it starts to affect our daily use.

Therefore it is a common concern for potential electric vehicle (EV) drivers who worry about their car’s battery life. And the cost of replacement

EV batteries can outlive the cars they power.

EV Battery Disposal Yet, this fear is misleading as EV batteries can last between 15-20 years or around 100,000 to 200,000 miles, which is longer than an average car’s lifespan of 12 years.

To ensure the battery’s long life , EVs have built-in battery management software (BMS) that regulates charging and discharging to protect battery cells.

To help your EV battery last longer, we recommend following these tips: keep the charge between 20 and 80 % for your daily use, steer clear of charging in extreme temperatures, and avoid charging every night. These easy steps can make a big difference in your battery’s lifespan!

Second Life

As time goes by, an electric vehicle may reach the end of its lifespan, but its battery can still keep a large part of its original capacity.

Nissan, a leading manufacturer of EVs, even after years of heavy usage, old EV batteries can maintain 60 to 70 per cent of their original capacity.

Although the battery’s power may not be enough to operate another electric vehicle, it can still be utilised for low-energy tasks, such as stadium lighting.

In the future, as V2I and V2H technology become more popular, old EV batteries can serve as energy storage solutions for homes, businesses, and the power grid.

Promoting the reuse of EV batteries through second-life programs can extend their useful lifespan before disposal is necessary.

It’s important to note that electric car batteries need a significant amount of cobalt, often mined in the Democratic Republic of Congo, where human rights violations and child labour are prevalent.

In addition mining also harms the environment, causing pollution and other ecological concerns.

What are the components of an EV Battery?

It is a common fact that lithium-ion batteries contain lithium, but have you ever wondered about the other materials required for their production? The manufacturing of a Li-ion battery requires the creation of several layers throughout the process.

However, like other batteries, these batteries have a cathode with a positive charge, an anode with a negative charge, and an electrolyte separating them.

The cathode generally comprises a combination of lithium, nickel, cobalt, and manganese, whereas the anode primarily comprises graphite.

Finally, an aluminium or steel casing encloses the individual cells, holding the battery pack together and protecting it against mechanical damage.

Breaking Down an EV Cell

The battery pack comprises several interconnecting modules, each resembling an AA battery. Each of these modules consists of hundreds of individual cells.

The Cathode makes up 51% of the battery’s cost, and the quality of the components, Lithium, Nickel, Cobalt, and Manganese, determine the battery’s power and capacity.

The graphite-based electrode known as the anode holds a negative charge.

The separators prevent contact between the cathode and the anode; The separators used are usually made of Polyethylene (PE), but ceramics are a viable option.

The electrolytes used are a chemistry of organic solvents capable of dissolving the lithium salt and provide a conductive medium for the movement of lithium ions between the battery’s electrodes during charge and discharge cycles.

The battery housing and casings to protect the battery packs are usually aluminium.

Table of Materials – EV Battery Disposal

| Raw Material | Where it Comes From | Environmental Impact |

|---|---|---|

| Lithium (Lithium is the lightest metal known and floats on water due to its low density.) |

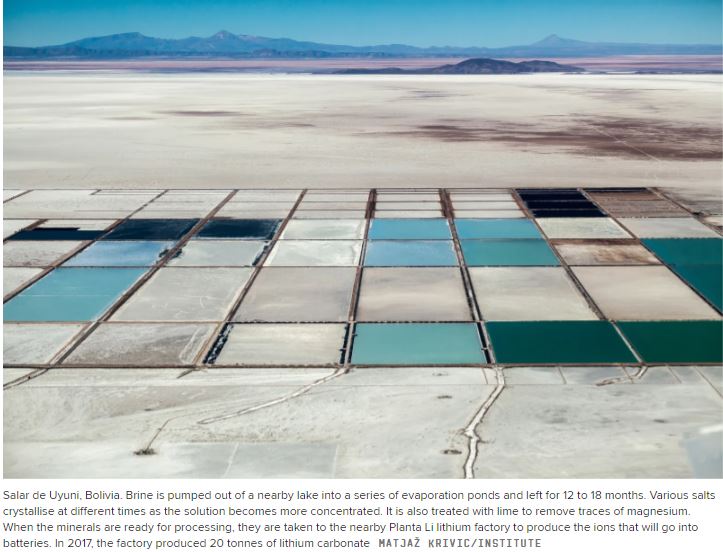

The element lithium is sourced from brine deposits and found in salt lakes in Australia, Chile, and China. | Extracting lithium is fairly low-cost and efficient, but it demands an enormous amount of water, reaching up to 500,000 gallons per ton of lithium. |

| Nickel (Cathode high energy density.) |

Nickel is mined from impure ore found in nature. It is extracted and refined to become useful. Russia, Australia, Indonesia, and Canada are the top nickel producers. | Nickel mining generates a lot of waste due to low concentrations of valuable nickel in the ores. Proper disposal of this waste is a major concern. |

| Cobalt (Cathode heat stabiliser.) |

The Democratic Republic of Congo accounts for two-thirds of global Cobalt production. EV batteries use 42% of the capacity. | Cobalt is a natural element, but too much exposure can harm health. Its production is often linked to worker exploitation, lack of regulation, and environmental damage. |

| Manganese (Cathode Stabilizer.) |

Manganese Ore mines are found in Mexico, Australia China, with South Africa having the largest concentration. | Manganese is safe in low levels in soil and water, but a mismanaged redox processes in coastal ecosystems can be harmful. |

| Graphite (Anode) |

The biggest mine is in Mozambique, with large deposits in Turkey, Brazil, and China. | Natural Graphite/Carbon is fine. Synthetic graphite production emits hazardous emissions due to its energy-intensive heat treatment process. |

| Aluminum (Bauxite) (Alumina Compound.) |

One ton of aluminium needs 2 tons of alumina, which needs 4 tons of dried bauxite. Main Sources: Guinea, Vietnam, and Australia | Aluminium is light, conducts heat well, has a minimal environmental impact and is infinitely recyclable. |

Legislated Cobalt Mine in Australia (pic Foreign Brief)

Battery Management Systems

The Battery Management System (BMS) regulates and optimises the battery’s performance. The BMS closely monitors and adjusts the charge level of every cell, and decides which cells should be charged or discharged

The temperature of the battery pack is also constantly tracked. The BMS can automatically adjust energy usage if any aspect of the battery’s operation falls outside the normal range. This is a critical function as it protects the battery pack and alerts the driver if necessary.

A battery management system is also necessary to properly manage the electrical system. It must have well-maintained wiring, connections, fuses, and other vital electrical components.

Just like smartphones and laptops, EV batteries also experience heating during operation. Due to their large size, electric car batteries generate substantial heat that requires dissipation.

Fortunately, the battery cooling system is in charge of this task, which includes a sealed coolant that transports the heat away from the battery cells and releases it into the air.

What are the most common methods for EV battery disposal?

Sadly, Landfilling is one of the popular options and is a straightforward and relatively inexpensive disposal method.

Leaching is risky if EV batteries are dumped in landfills or improperly stored. Heavy metals and toxic chemicals can seep into the soil and contaminate groundwater, affecting nearby ecosystems and could enter the food chain.

Total recycling involves extracting valuable materials from the batteries. These materials can be reused to produce new products. Recycling helps conserve resources and reduces the need for mining raw materials.

There is a growing focus on creating battery chemistries that are both sustainable and efficient, as well as enhancing recycling processes and infrastructure to ensure a more responsible approach to battery usage.

The good news addresses this common concern: electric car batteries are recyclable. Through various techniques, it’s worth noting that the field of EV battery disposal is constantly evolving as technology advances and new solutions emerge. It’s possible to recover up to 95% of the raw materials.

What are the environmental impacts of disposing of EV batteries improperly?

The Improper disposal of electric vehicle (EV) batteries can have significant environmental impacts. EV batteries contain heavy metals like lithium, cobalt, nickel, lead, and other toxic chemicals.

Improperly handling EV batteries is a serious matter that can cause incineration or fires, releasing toxic fumes into the air. These fumes contain harmful gases and particulate matter that can contribute to air pollution, posing significant health risks to humans and wildlife.

How can the EV industry improve its EV battery disposal practices?

Establishing a robust battery recycling infrastructure is crucial. This involves setting up specialised facilities capable of safely and efficiently recycling EV batteries. Hold manufacturers accountable for the entire lifecycle of their products.

Promoting the reuse of EV batteries through second-life programs can extend their useful lifespan before recycling becomes necessary.

Did you know that EV batteries that are no longer suitable for cars can still be repurposed for stationary energy storage applications? This not only provides value but also helps reduce the need for immediate recycling..

Several automobile manufacturers and battery producers have collaborated with recycling firms to guarantee the proper disposal and recycling of electric vehicle batteries.

Volvo’s Battery Loop project involves developing electric car batteries that can be used in a solar energy storage system, providing power for charging stations for cars and bicycles.

Honda works with Société Nouvelle d’Affinage des Metaux (SNAM) to collect and recycle batteries for secondary use or to extract valuable elements.

Jaguar Land Rover has created a portable electric car charger called the Off-Grid Battery Energy Storage System (ESS) using battery packs from I-Pace prototypes, which have a capacity of 125 kWh and features integrated solar panels. This commercial use is for situations where there is no access to the main electricity..

Specialist Re-Cycling

When dealing with the disposal of EV batteries, recycling is the most preferred method. Recycling involves extracting valuable materials from the batteries, such as lithium, cobalt, nickel, and other metals.

These materials can be reused to produce new batteries or other products. Recycling helps conserve resources and reduces the need for mining raw materials.

Accessing these valuable materials requires specialised recycling facilities that can handle the unique characteristics of these batteries.

These facilities have the necessary equipment to safely dismantle and recycle batteries while minimising their environmental impact.

Wiring and plastics can be stripped and recycled. Accessing the precious metals in the battery cell electrolyte, can be risky due to their flammability, explosiveness, and toxicity. These hazards must be dealt with before cell components can be recycled.

Electrochemical refining

One of the companies at the forefront of sustainable recycling is Nth Cycle from Massachusetts. It uses metals processing technology, and electrochemical refining, which allows battery manufacturers to convert lower-grade critical metals into EV-battery grade on-site without heating to 1,400°C.

The company’s approach prevents large portions of cumbersome and dirty metal supply chains for crucial EV battery metals like nickel.

According to Nth Cycle, both new and existing batteries can use this cleaner technology. As a result it can speed up the process of circular economy for lithium-ion batteries and recycling.

In the UK, Veolia launched its first battery recycling facility in the West Midland in January 2022 to recycle 20% of the UK’s electric vehicle batteries that reach the end of their life by 2024.

This will be accomplished using an innovative “urban mining” process, which is more efficient than conventional mining practices and emits 50% fewer greenhouse gases.

Trading Places

The other good news is that there is an international commodity market for recyclable EV batteries, which means that there is money available for investment in the technology of recycling.

Governments worldwide are now supporting the initiative to mandate the development and production of EV batteries that are easily recyclable.

Black Mass refers to the commodity trade of crushed and shredded End of Life (EoL) battery cells, also known as e-waste.

This mixture contains valuable metals such as lithium, manganese, cobalt, and nickel. The process involves collecting, sorting, discharging, and disassembling waste batteries.

The government’s zero-emissions policies for 2030-35 are driving a significant surge of interest in a relatively new commodity.

Experts forecast a massive surge in demand for lithium batteries, with a projected increase of six times within the next ten years..

Speculators in this business see Transport as the main driver of growth, representing more than 80% of the market.

Forecasters expect the lithium, nickel, and cobalt markets to be in deficit in 2033, driving demand for recycled materials.

However, End-of-life (EoL) supply won’t become the main source of battery scrap until 2033. The black mass market is new and opaque, presenting a new business opportunity.

Types of black mass

Heating black mass to 1,400°C for refinement with pyrometallurgical methods results in the loss of lithium to slag.

However, this method is not practical for refining Lithium Iron Phosphate (LFP) black mass. It is, however, suitable for refining Lithium cobalt (LCO) and nickel cobalt manganese (NCM) black mass.

Hydrometallurgical refining is not a cost-effective option for recycling LFP due to its exorbitant cost per ton of black mass.

However, in Asian countries with high lithium recovery rates, this method of recycling is common practise.

The process of electrochemical refining is a recent technology. It offers reduced operational costs and a broader range of capabilities in recycling black masses, such as LFP.

LFP is gaining popularity globally, particularly in China, resulting in increased LFP black mass production.

Alternative Battery Technology

Sodium-ion batteries function similarly to lithium-ion batteries and are recyclable using the same methods.

The advantage of sodium-ion batteries lies in the fact that sodium is more abundant and less expensive. However, the technology still needs further development to achieve the same performance rate as lithium-ion batteries.

Solid-state batteries

Major car manufacturers are currently exploring solid-state batteries because they are more efficient and less prone to flammability compared to lithium-ion batteries.

However, solid-state batteries present unique recycling challenges. They can store more energy and charge quicker and more safely than lithium-ion batteries.

Solid-state batteries utilise thin solid layers for their electrolytes, making them significantly more stable and less flammable than the liquid electrolytes found in lithium-ion batteries.

Despite these benefits, electric cars do not currently use solid-state batteries. This is due to the difficulty of scaling up production to meet the necessary volume for widespread usage.

The future of battery recycling may involve creating new batteries from old ones. However, solid-state electrolytes need good conductivity, which can be challenging since they are thin and fragile. This can result in a manufacturing cost of around eight times higher than other types of batteries.

Nissan has launched “Ambition 2030”, which is their commitment to electrification. The plan includes releasing a solid-state battery car by 2028 from their pilot plant in Yokohama, Japan. Nissan also aims to reduce the costs of solid-state batteries to eliminate the price gap between electric and combustion-engine cars.

EV Battery Disposal – FAQs

The amount of available lithium is uncertain, but current estimates suggest around 22 million extractable tons worldwide. This figure constantly changes as we find new sources and better

extraction methods.